DC250 / DC350 Semi-Rotary Die Label Finishers

Quickly turn printed rolls into fully-finished labels

Transform your label production process with the Afinia Label DC250 and DC350 Digital Label Finishers. Engineered for precision, efficiency, and versatility, these state-of-the-art machines are your all-in-one solution for producing fully-finished labels in-house. Whether you’re a private labeler or a large brand, the DC250 and DC350 are designed to meet your needs for high volumes of labels and repeat sizes, streamlining your operations and enhancing your product offerings.

- Precision Die Cutting

- Automatic Web Guidance

- High-Speed Efficiency

- Versatile Material Compatibility

DC250 / DC350 Details

Elevate your label production with the groundbreaking Afinia Label DC250 and DC350 Digital Label Finishers. Experience unmatched precision, durability, and versatility that will transform your in-house label creation process.

Capabilities

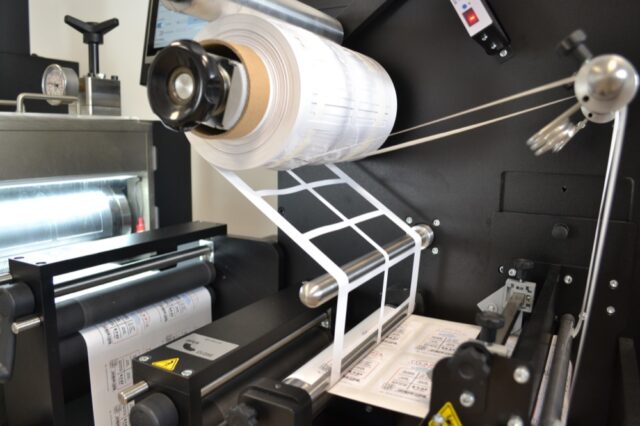

- Advanced Lamination Capabilities: With our machines, apply a protective layer that shields your labels against wear and tear, ensuring they withstand harsh conditions while maintaining a premium look. Perfect for products that demand a durable and long-lasting finish.

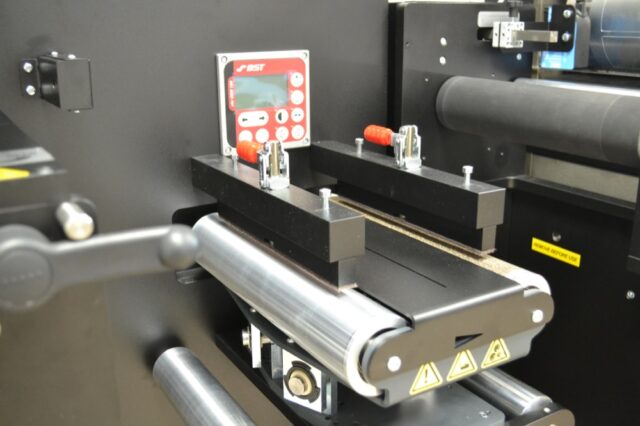

- Precision Die Cutting with a Twist: Leverage our innovative semi-rotary die cutting technology to precisely cut any label shape quickly and accurately. What sets the DC250 and DC350 apart is their use of magnetic die cylinders and flexible steel dies. These are not only fast and cost-effective to produce but also allow for rapid job changeovers, ensuring your production keeps pace with demand.

- Efficient Waste Removal: Our integrated waste removal system simplifies your workflow by automatically eliminating excess material post-die cutting, leaving behind perfectly shaped labels without the fuss.

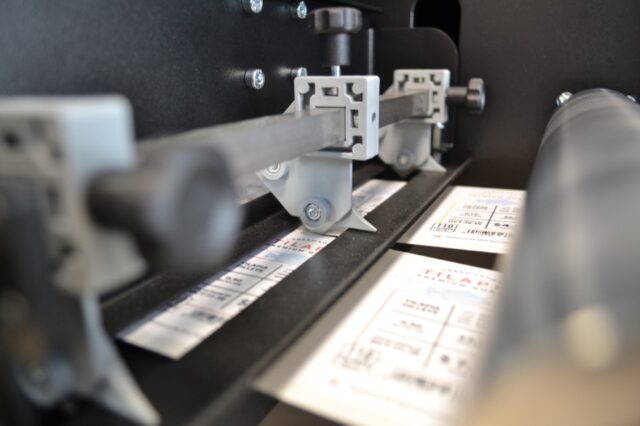

- Streamlined Slitting and Rewinding: Transform wider rolls into narrower ones and rewind them into finished rolls ready for application. This feature maximizes production efficiency, enabling the creation of multiple label sizes from a single print run effortlessly.

- Optimized for High Volume Production: The DC250 and DC350 are engineered to meet the rigorous demands of high-volume production without compromising on quality or reliability.

Empowering brands and private labelers

Imagine having complete control over your label production, with the flexibility to respond instantly to market trends, the ability to create custom, high-quality labels in-house, and the efficiency to reduce costs and turnaround times significantly. The DC250 and DC350 not only offer this but also ensure your labels stand out with a premium finish, thanks to their advanced features like magnetic die cylinders for quick customization and flexible steel dies for economical production.

Benefits

- Full In-House Production Control: Say goodbye to reliance on external suppliers and inventory shortages. Welcome faster turnaround times and unmatched flexibility.

- Unmatched Customization and Versatility: Quickly adapt to changing designs and sizes, thanks to the quick job changeovers enabled by our innovative die technology.

- Superior Product Presentation: Ensure your products make a lasting impression with labels that feature a premium look and feel, enhancing your brand’s perception.

- Simplified, Efficient Workflow: From pre-printed roll to ready-for-use labels, streamline your production process, reducing manual handling and improving overall efficiency.

Ideal for private labelers and large brands: Whether you’re aiming to boost your brand’s appeal or ensure your products stand out with high-quality labels, the DC250 and DC350 are your go-to solutions. Ideal for any industry requiring consistent quality and high-volume label production, such as food and beverage, cosmetics, and health care.

Schedule a Demo

Don’t let outdated production methods hold you back. Upgrade to the Afinia Label DC250 and DC350 Digital Label Finishers and revolutionize your label production. Contact us now for a demonstration or to learn more about how these machines can elevate your labeling process to new heights.

Specifications

DC250 | DC350 | |

|---|---|---|

| Semi-Rotary Speed | Up to 30m/min | Up to 30m/min |

| Web Width | Up to 250mm (9.84") | Up to 350mm (13.78") |

| Input Roll Diameter | 500mm (19.68”) | 500mm (19.68”) |

| Laminate | Economical, self-wound and supported laminate (on a liner) | Economical, self-wound and supported laminate (on a liner) |

| Die Head Lateral adjustment | +/- 60mm | +/- 60mm |

| Max. Diecutting Width | 230mm (9") | 330mm (13") |

| Max. Diecutting Length | 360mm (14.17") | 360mm (14.17") |

| Die Type | Flexible steel | |

| Die Sizes | 130mm (5.11") to 360mm (14.17") | |

| Max. Finished Label Rewind | 400mm (15.74") | 400mm (15.74") |

| Max. Waste Matrix Rewind | 300mm (11.8") | 300mm (11.8") |

| Minimum Slitting Width | 19mm (0.75”) | 19mm (0.75”) |

| Number of slitting blades | up to 12 | up to 15 |

| UV Varnish module | YES | YES |

| Core Holder | Mechanical (3") | Pneumatic (3") |

| Registration Sensor / Mark | Laser / 4mm x 4mm (0.16" x 0.16") | Laser / 4mm x 4mm (0.16" x 0.16") |

| Power | 100-240V ~ 1Kw, 50/60Hz | 100-240V ~ 1Kw, 50/60Hz |